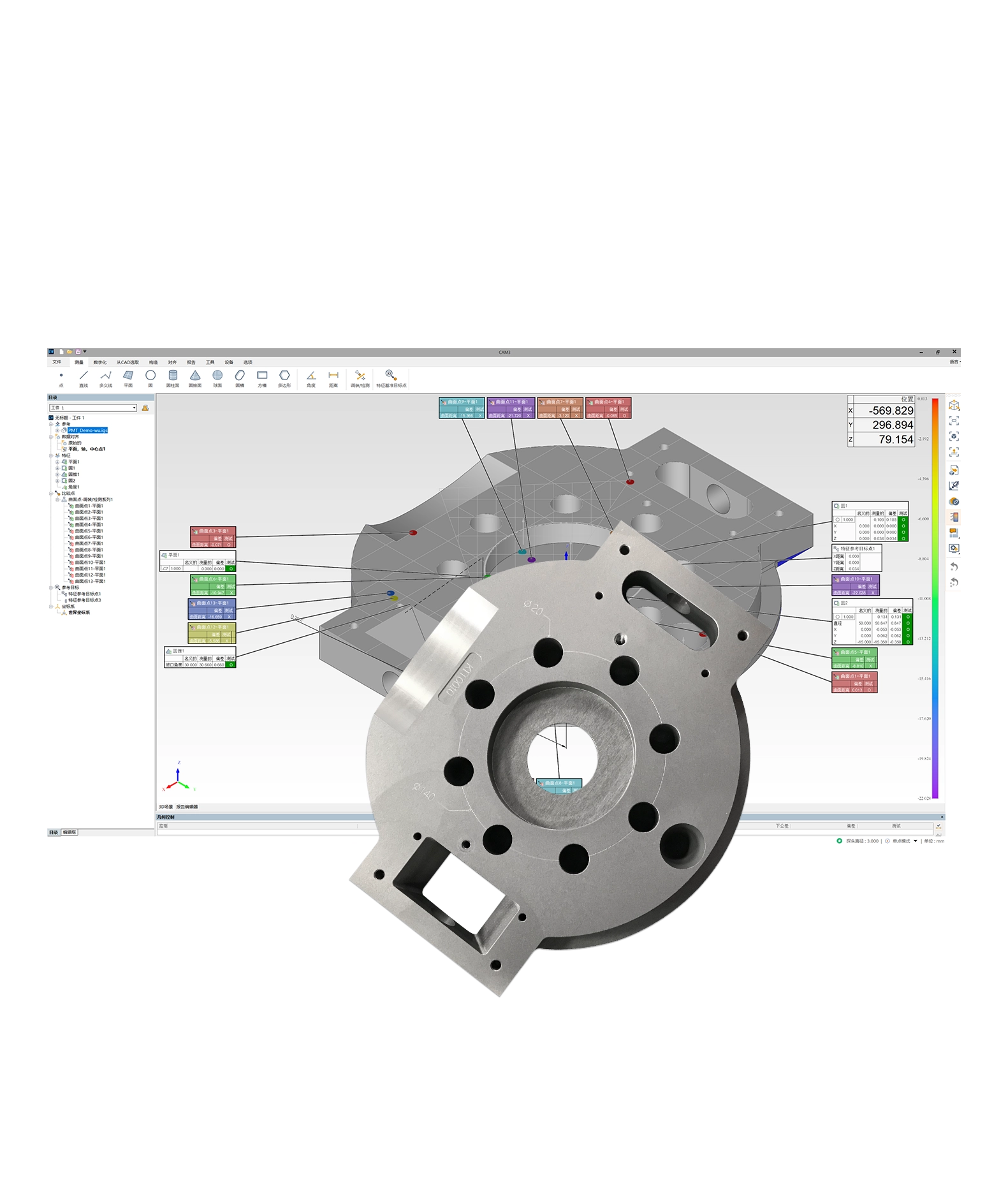

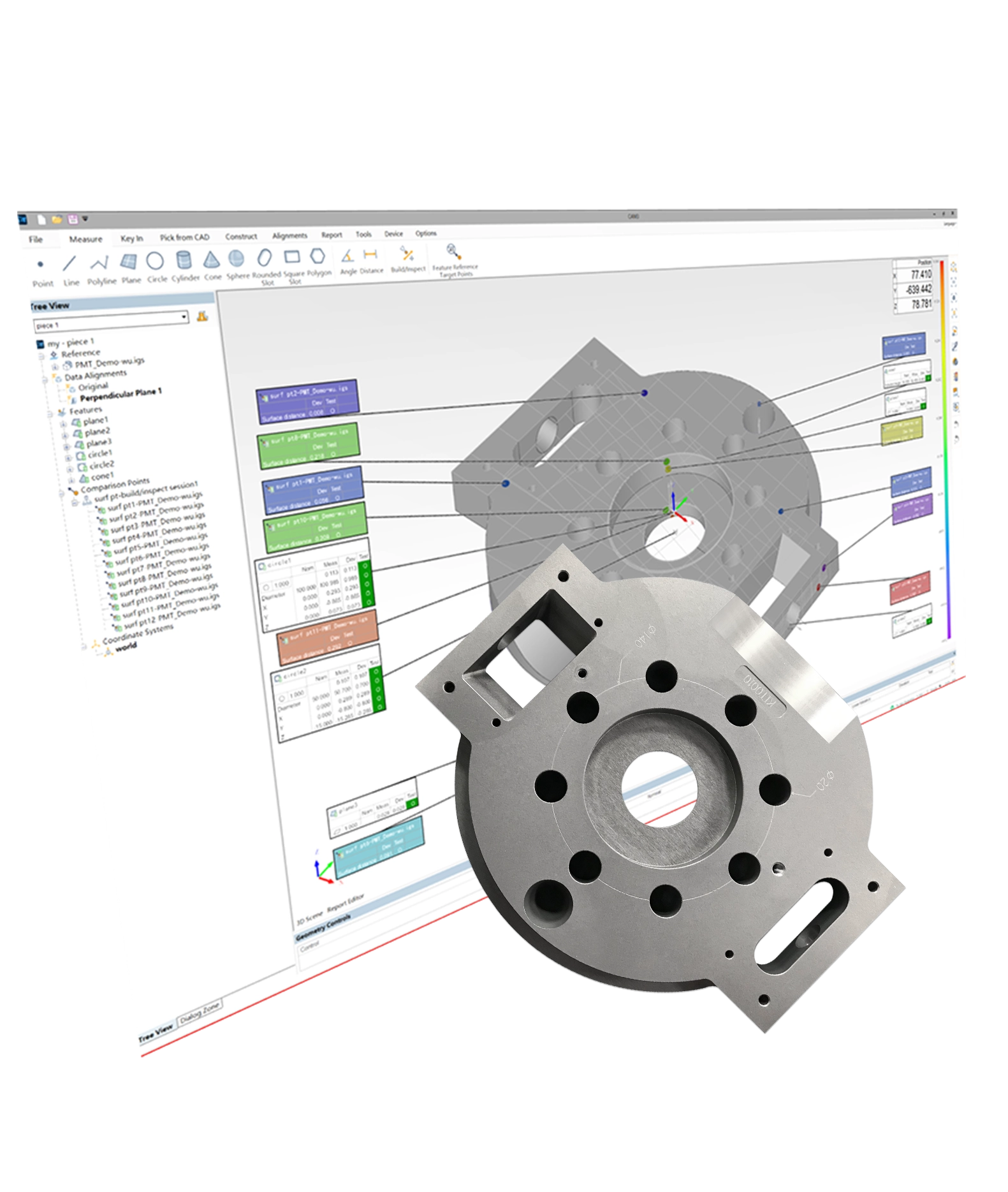

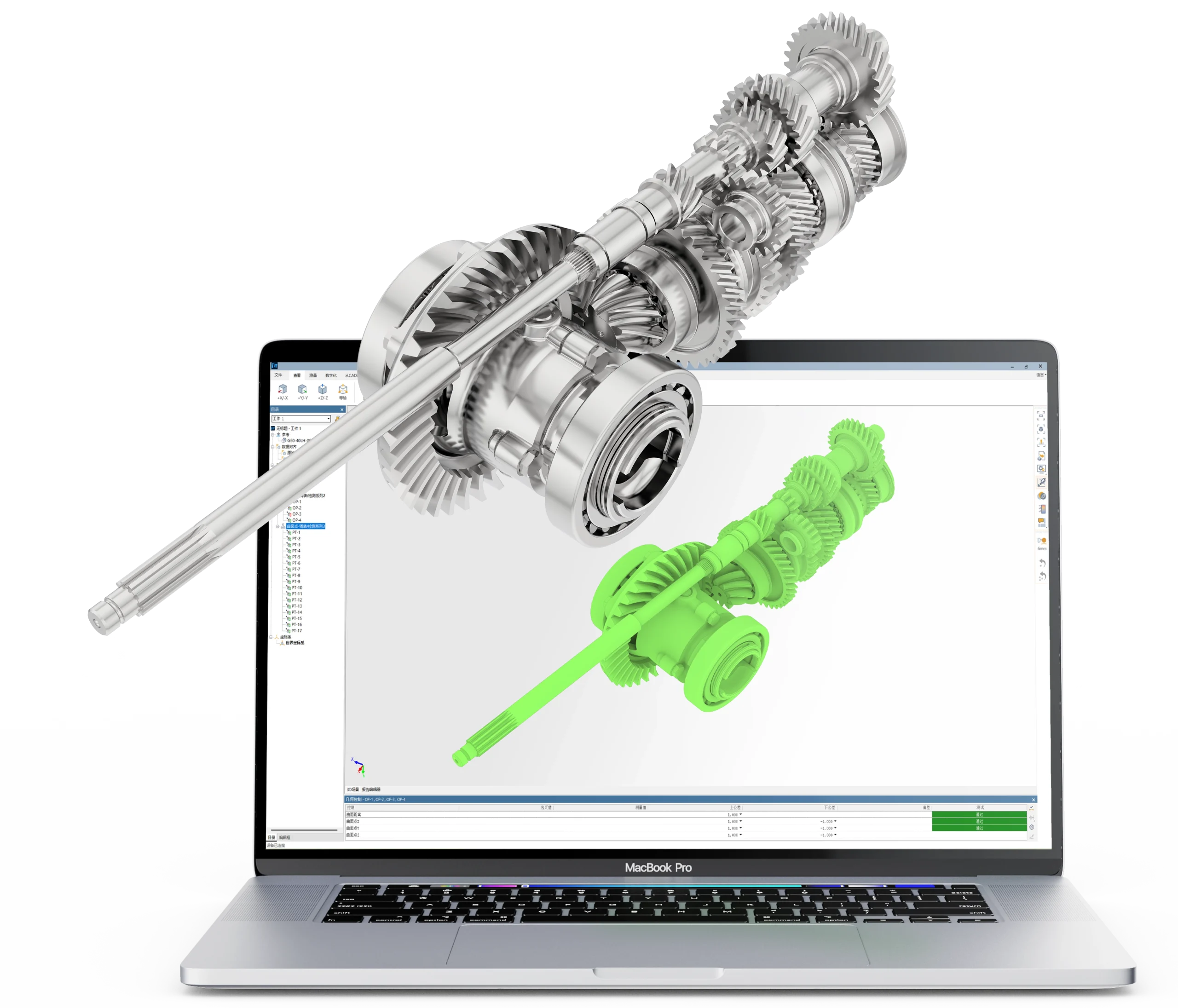

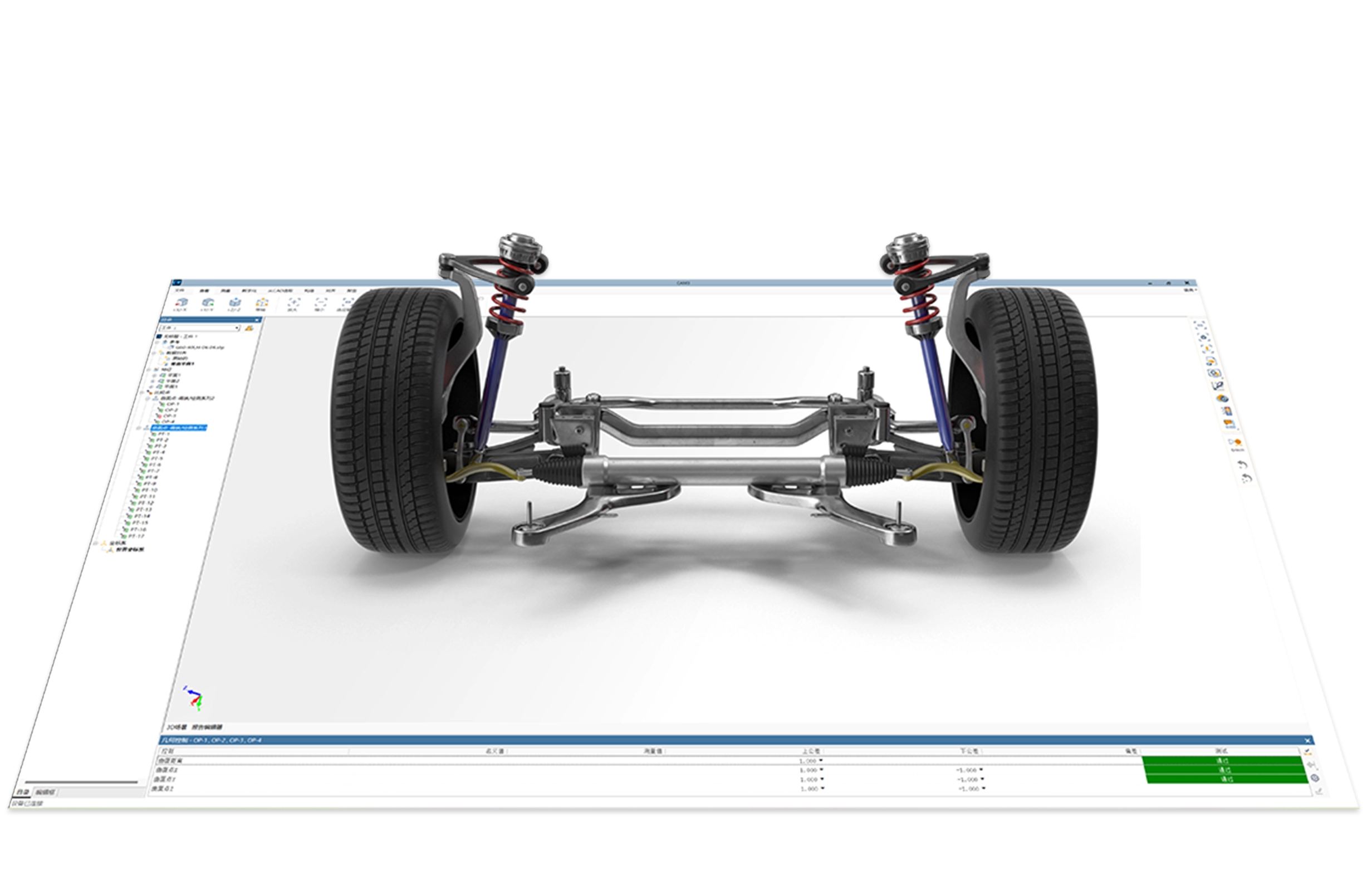

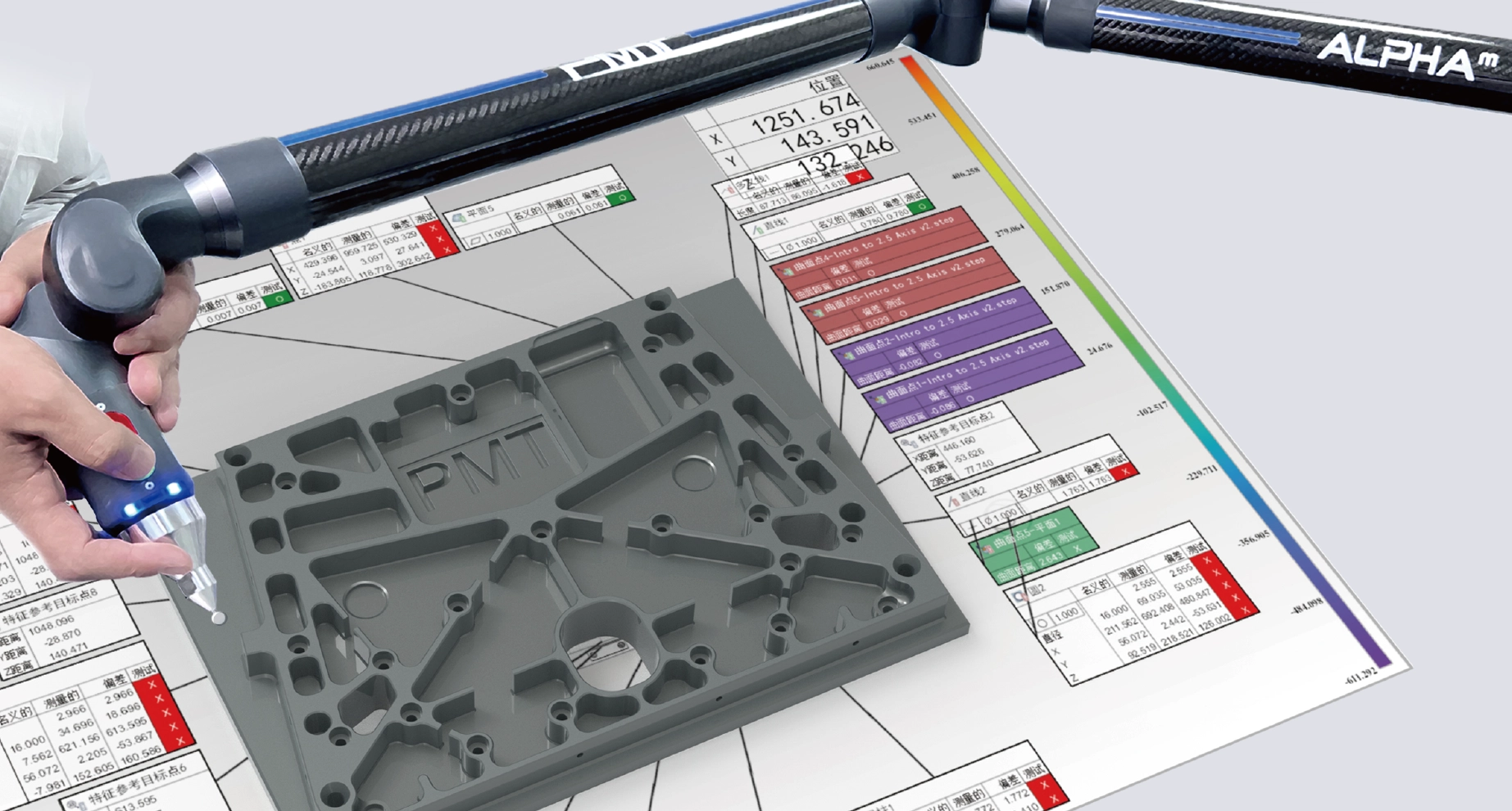

CAM3 helps measurement objects obtain results by calculating the dimensions and deviations.

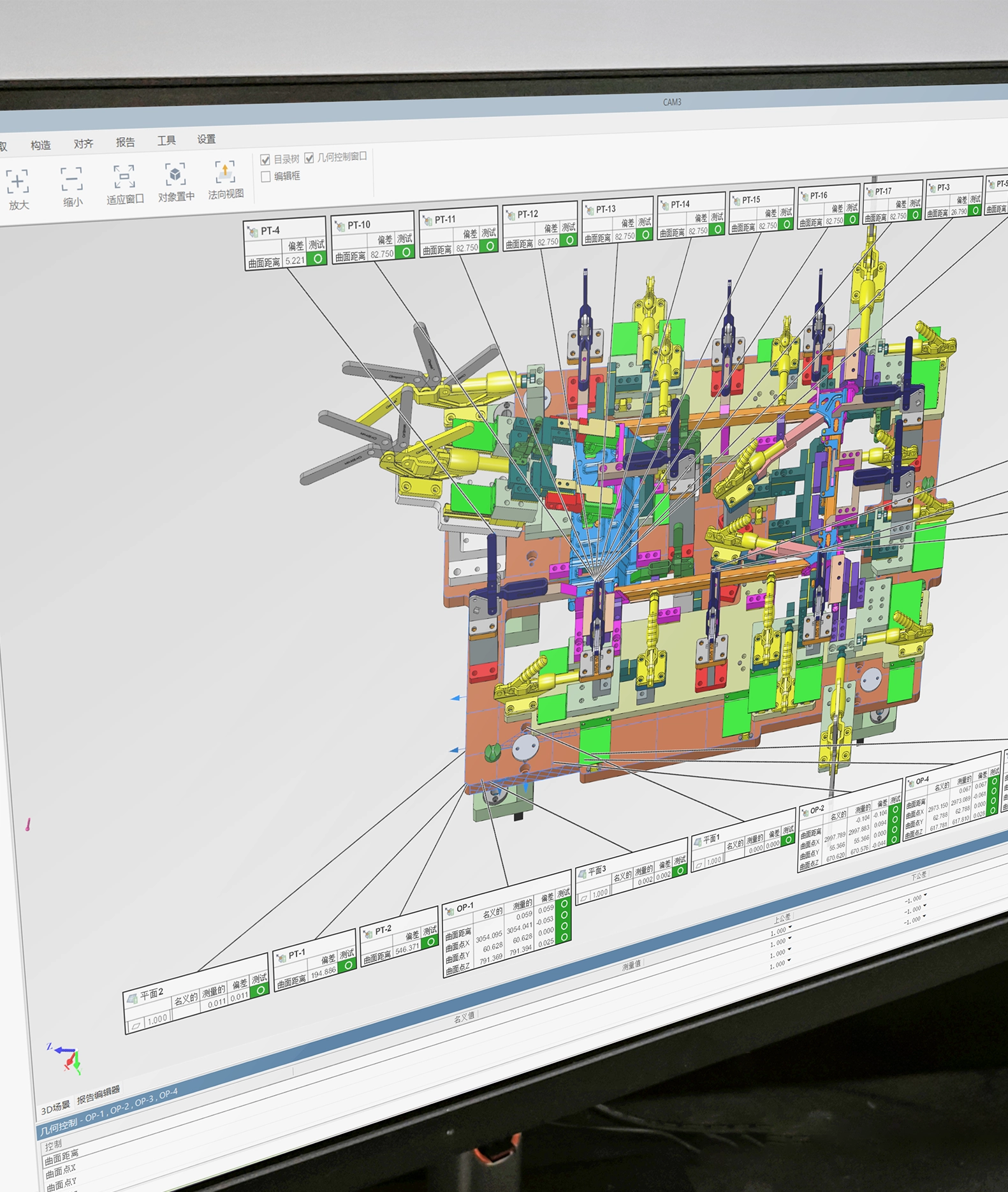

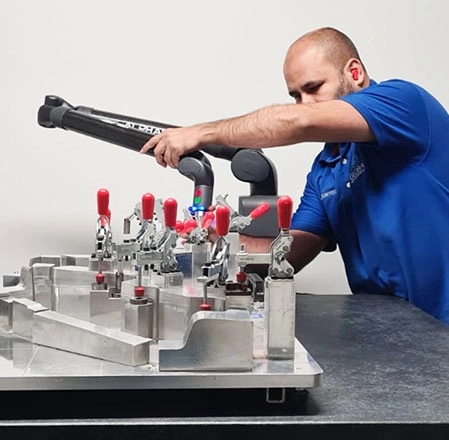

● Measurement objects are measured in real time and compared with the design drawings to make sure the objects meet certain requirements.

● Quality control and inspection are ensured in production.

● The sizes and shapes of objects are measured to see if any deviations and defects exist so as to guarantee the quality.