The Importance of Measurement of Mechanical Frames and Other Components

As a core part of the chassis, the frame must satisfy the following two critical requirements:

- Assembly Integration: Provide precise installation and positioning for the engine, suspension, transmission system, etc.

- Load Assurance: Ensure that frame deformation under extreme conditions does not cause part interference.

PMT Portable CMM Facilitates the Inspection of Agricultural Machinery Frame

As a high-precision portable coordinate measuring machine, the PMT portable measuring arm has emerged as an essential device for quality control in the agricultural machinery industry. The core application scenarios of the PMT portable measuring arm are as follows:

A. 3D Dimensional Inspection of Mechanical Frame

- Portable CMM replaces traditional caliper/gauge for measurement

- Digital comparison of key dimensions (length/width/height)

- Supports standardization of assembly lines

B. Precision Measurement of GD&T

- Analysis of flatness/perpendicularity/coaxiality

- Accuracy up to 0.05mm

- Precontrol of assembly gaps

C. Quality Inspection of Welding Parts

- Evaluate the welding joint angles, ensuring the welding strength and parts’ quality.

- Effectively control the accuracy of tooling , improving the yield rate of the product.

The Measurement Process and Digital Report of PMT Portable CMM

A. Arm Calibration: Follow the standard calibration process to check the accuracy of the portable measuring arm with a calibration cone.

B. Drawing Analysis: Determine the reference datum and measurement process based on the provided drawings.

C.Data Acquisition: Obtain actual data of the parts using the portable measuring arm, ensuring measurement accuracy while eliminating external factors that may lead to deviations.

D. Data Comparison: Import the CAD model into the software for real-time data comparison, analyze frame deviations, and generate a formatted report.

E. Result Evaluation: Analyze the frame quality based on the report, manage the assembly dimensions in advance, and implement adjustments or rework as required.

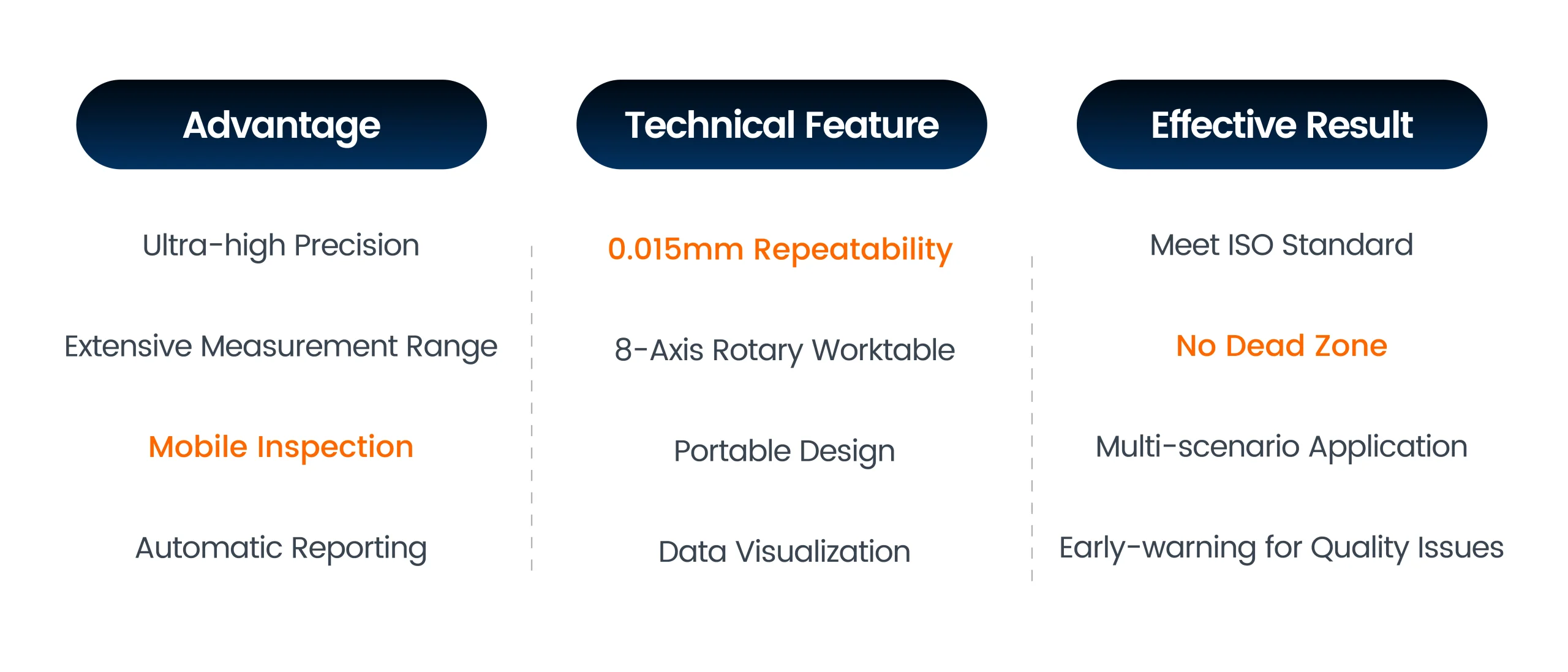

Core Advantages of PMT Portable CMM

Customer Feedback: PMT Portable CMM Contributes to the Transition from Quality Challenges to Industry Leadership?

Feedback from an agricultural machinery company:

1) Efficiency Improvement:

- Annual inspection capacity increased from 800 units to 2,800 units.

- Quality Breakthrough

- Welding defect rate reduced from 17% to 2.3%, awarded the provincial-level exemplary enterprise.

- After-sales claim costs reduced by 530,000 yuan per year.

6.PMT Portable CMM Set a New Benchmark for Innovation

The PMT portable coordinate measuring machine has proven to be a breakthrough in quality control for agricultural machinery frames. With its high-precision and flexible inspection solutions, PMT portable measuring arm has driven the agricultural machinery manufacturing industry toward intelligent transformation.