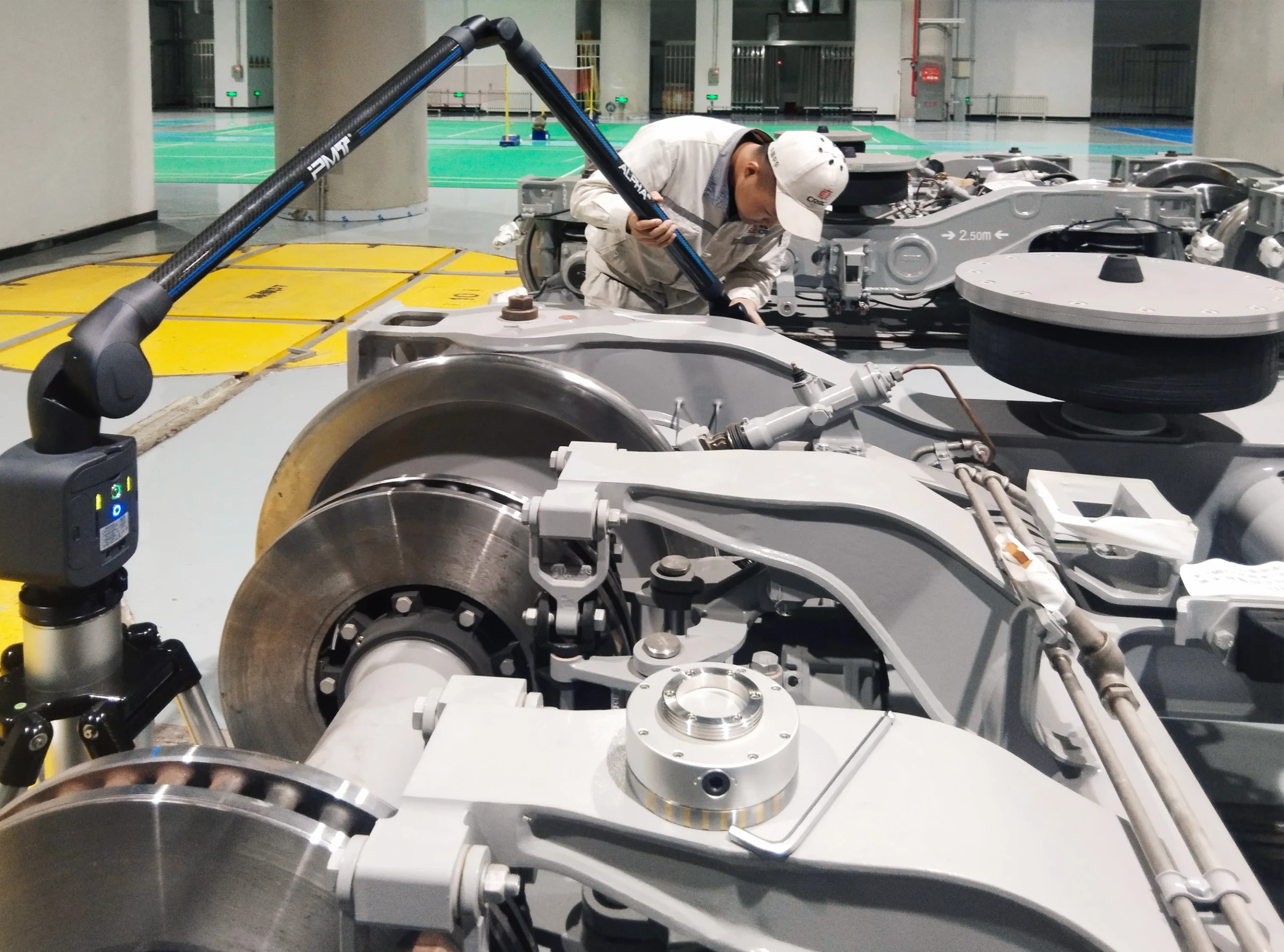

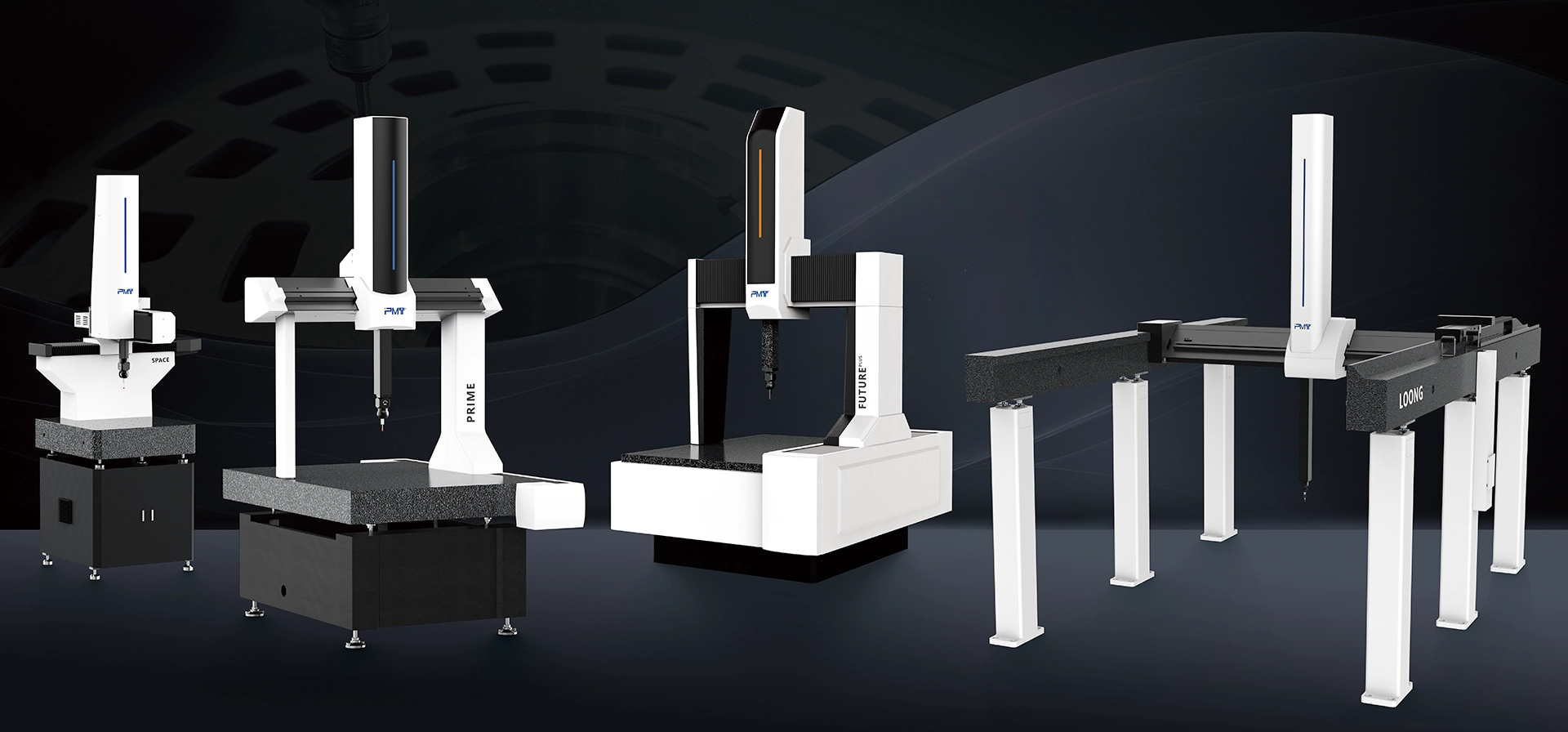

Whether it is in a laboratory with constant temperature and pressure or in the on-site assembly under changing environmental conditions, the PMT portable CMM can provide flexible and multi-angle solutions for the visible parts of the train such as bogies. In this way, the PMT portable measurement arm efficiently avoids manual errors in large, greatly improves the accuracy of measurement, and is more in line with the needs of modern rail transit testing.

- Key Points of the Measurement:

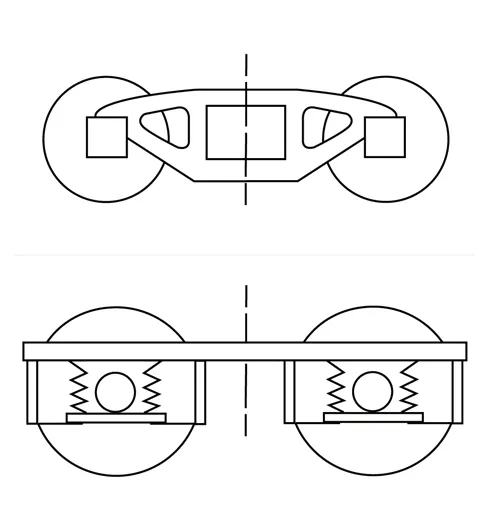

- Measure the parallelism, plane and surface of the four axle box parts of the bogie;

- Measure the size of the axle box diagonal (mostly ≥ 4000mm);

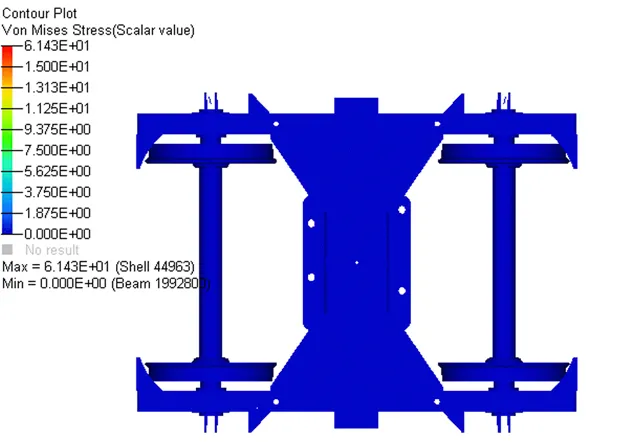

- ?Analyze data for compliance with technical requirements and instruct the assembly jobs;

- ?Provide professional measurement report at any time.

- Advantages:

- Measurement range/configuration: 4.0m/6-axis;

- Operating temp range: 5 – 45℃;

- Inspect whenever, wherever, without moving the bogie;

- Archived measurements for data traceability and analysis.