- Injection Molds

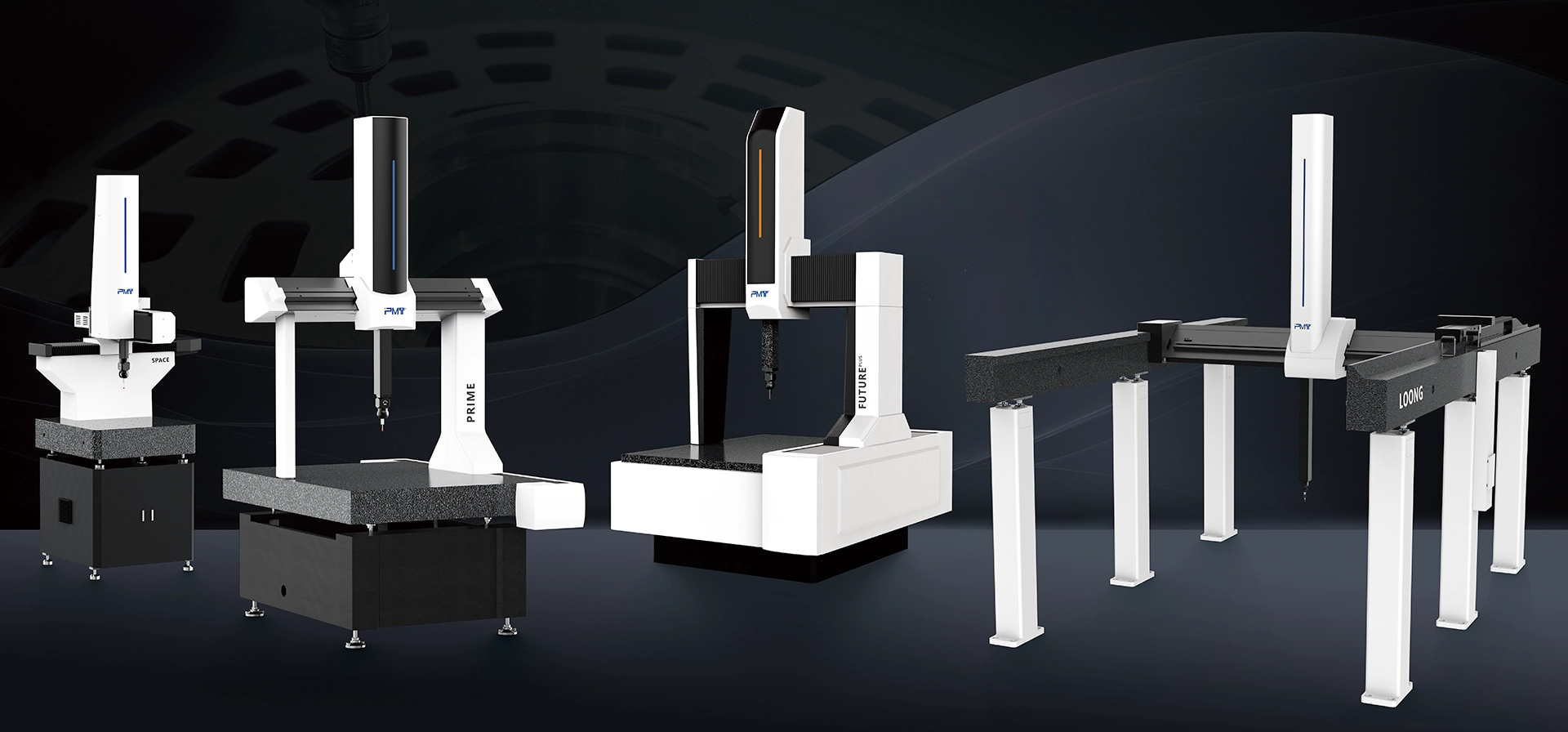

Injection molds are molds used to produce plastic products, and their precision and dimensional stability are essential for product quality. CMM can accurately measure the dimensions and shapes of injection molds to ensure they meet design requirements. For molds with complex shapes, non-contact measurement method such as laser scanning can be used for 3D measurements; For molds with simple shapes, contact measurement method such as a coordinate measuring machine is used.

- Die-casting Molds

Die-casting molds are used to produce metal castings, such as aluminum alloys, zinc alloys, etc. CMM can perform detailed measurements and analyses of die casting molds to ensure they meet production requirements. The shape accuracy of the die-casting mold requires that the shape of the cavity, core and other components of the mold be consistent with the design drawings, and there is no obvious deformation or deviation. Positional accuracy requirements as well as the relative position relationship of each component in the mold must meet the design requirements to ensure the shape and position accuracy of the die casting.

- Other Molds

In addition to the common mold types mentioned above, coordinate measurement machine can also be used to measure other molds, such as rubber molds, ceramic molds, glass molds, etc.

床模具】-1737615134.webp)

床模具1】-1737616287.webp)

床模具2】-1737616289.webp)

床模具4】-1737616295.webp)

床模具3】-1737616293.webp)