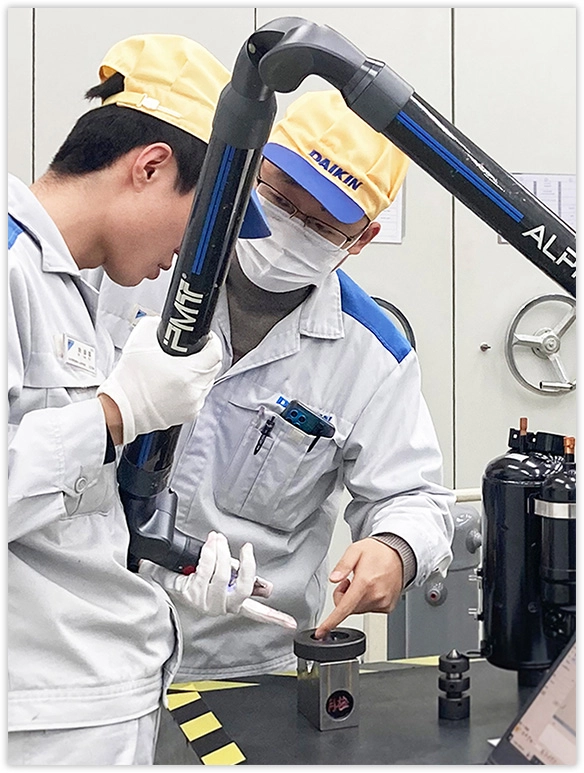

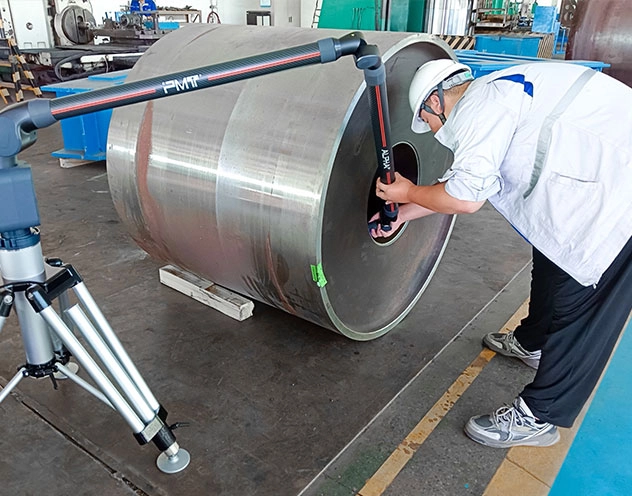

After extensive communication and analysis, PMT provided the customer with a customized solution. They used the PMT portable arm in almost every process such as inspection, adjustment, modification, prototyping and mold manufacturing, and finally got a professional report, helping them get this order.

Later, the PMT measuring arm was recognized by the head of the customer’s engineering department after the project had been completed. He said, “Thanks for the support from the PMT company. The product and report just exceeded my expectations. Previously, we used manual tools but the measurements were often inaccurate, resulting in delayed records. If we use traditional tools, it will take at least 3-5 people with calipers and feelers, and it may not even be possible to complete and win the order.”