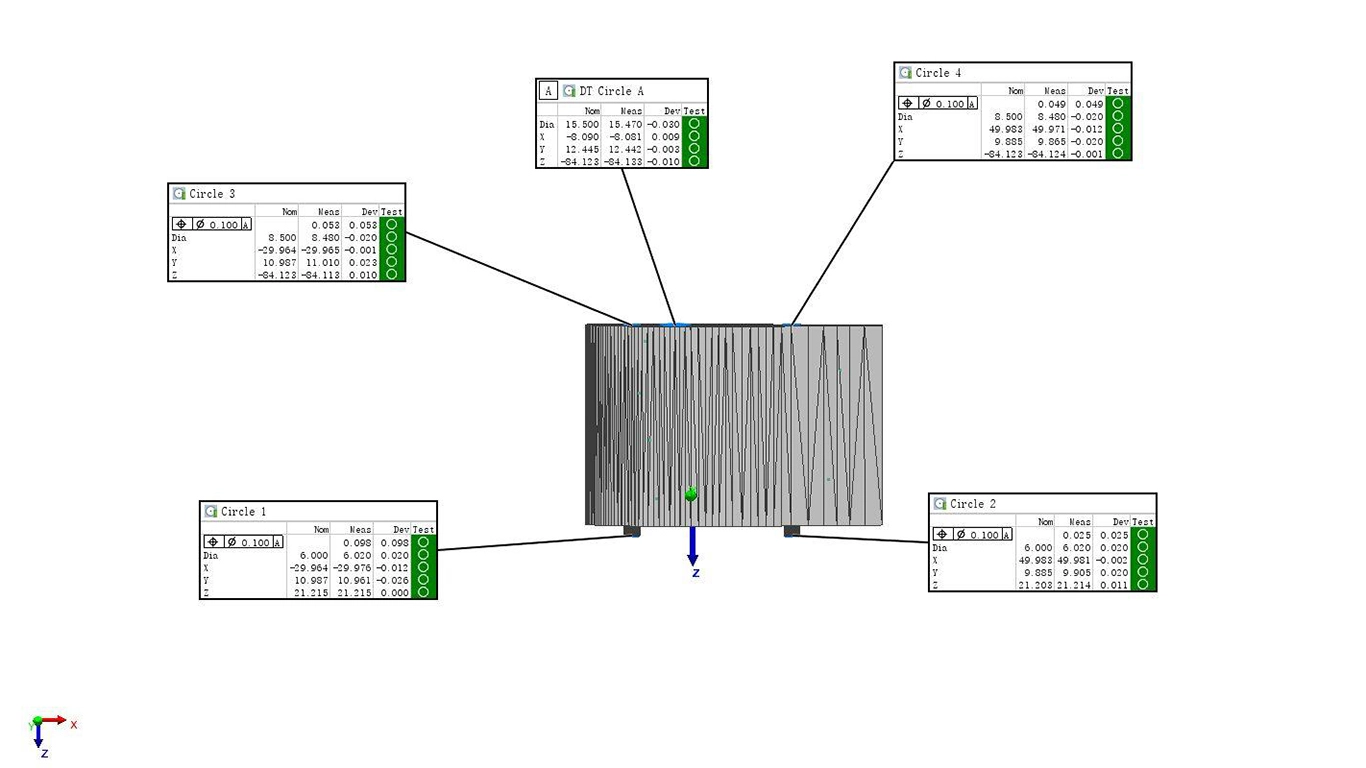

In Picture: During the measurement process, by comparing the measured data of PMT measuring arm with nominal data of the CAD model in real time, the technician can quickly find deviations that do not conform to the design. The portable CMM allows the customer to adjust their production processes in a timely manner and thus make ensure each structural part meets quality standards.

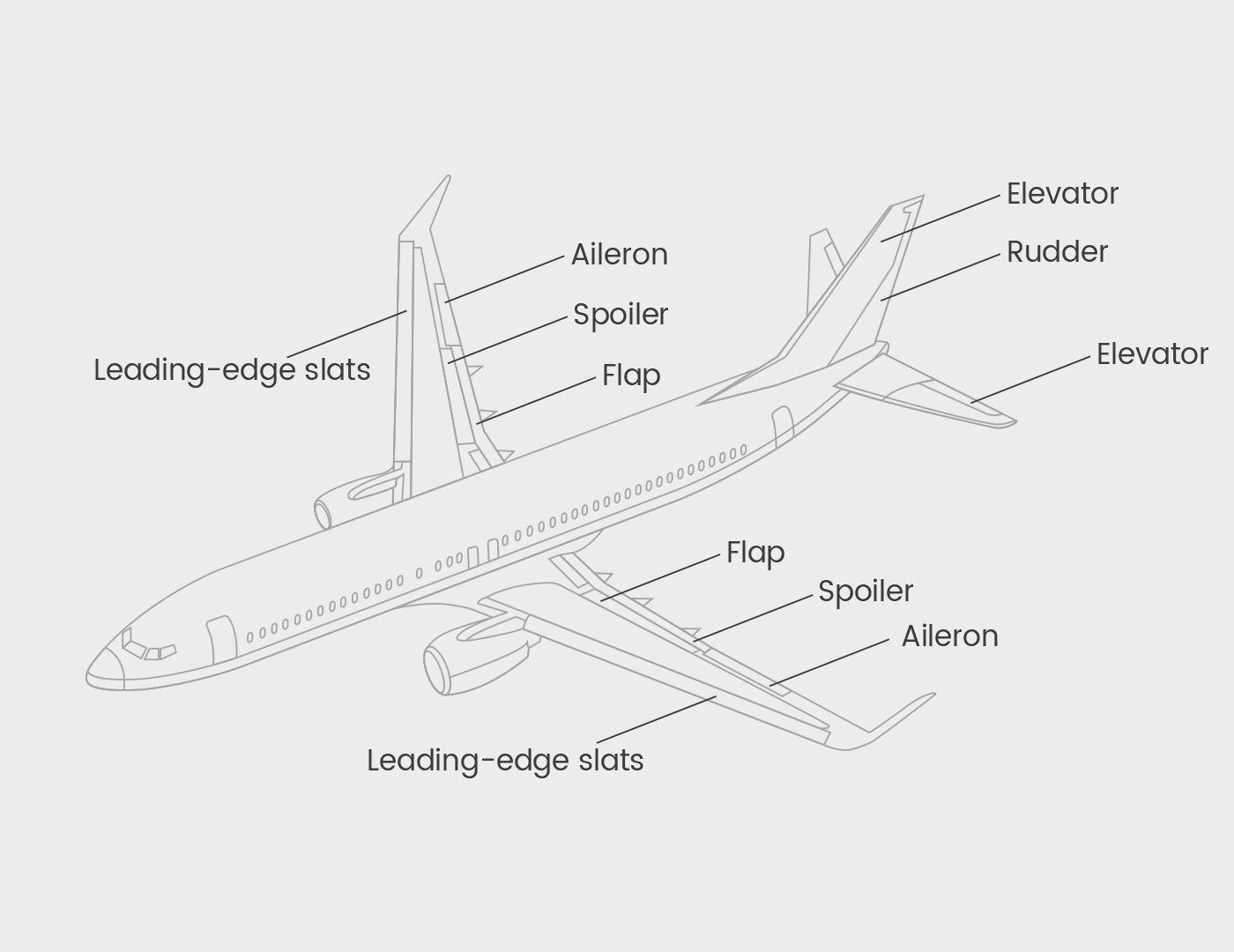

At the junction of the wing of the aircraft, the portable arm can precisely measure the key features such as the hole diameter, position and angle of the connector. The data can serve as a precise guidance when installing the components, ensuring a solid and reliable connection between the wing and the fuselage.