The clearance often exists in the assembly of various parts of engineering machinery, which results in qualified parts with unsatisfactory equipment operation. When using traditional inspection tools for assembly assistance, it is necessary to rely on additional references such as reference planes or rotation axes, which may indirectly lead to uncertainty in error.

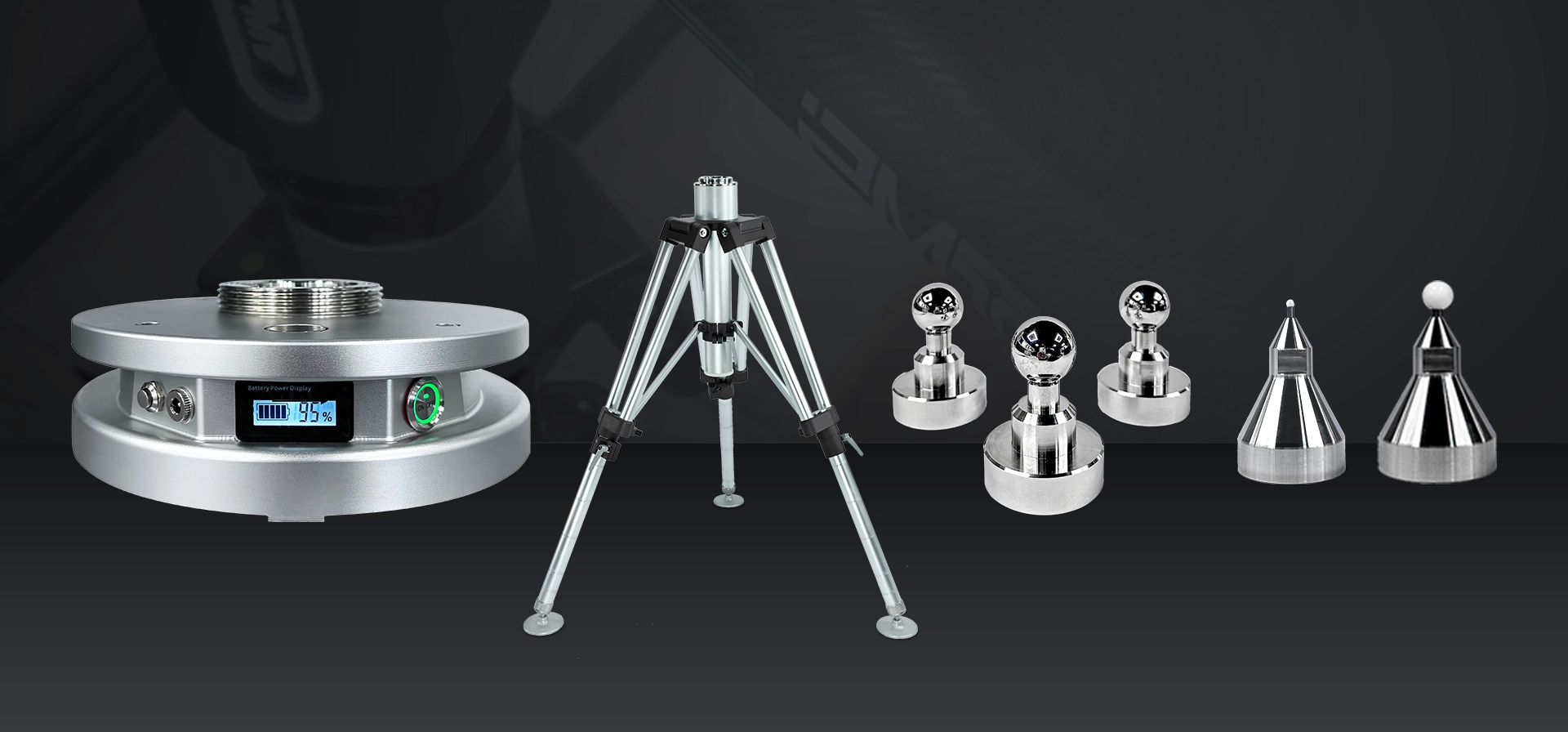

- Flexibility to Establish Coordinate System: PMT portable arm can use the installation surface of the assembly to establish a coordinate system, and then measure and verify the position of the assembled parts after assembly.

- Real-time Coordinate Function: When using PMT measuring arm, the coordinates of the probe sphere center are fed back in real time. This function of the portable CMM enables fine-tuning of assembly parts within the current coordinate system to enhance assembly precision and efficiency.

- Wide Applications: By combining the PMT measuring arm with the CMM, along with other intelligent manufacturing technologies, it is possible to achieve automated production and inspection so as to enhance the whole assembly precision.